Wir für Sie!

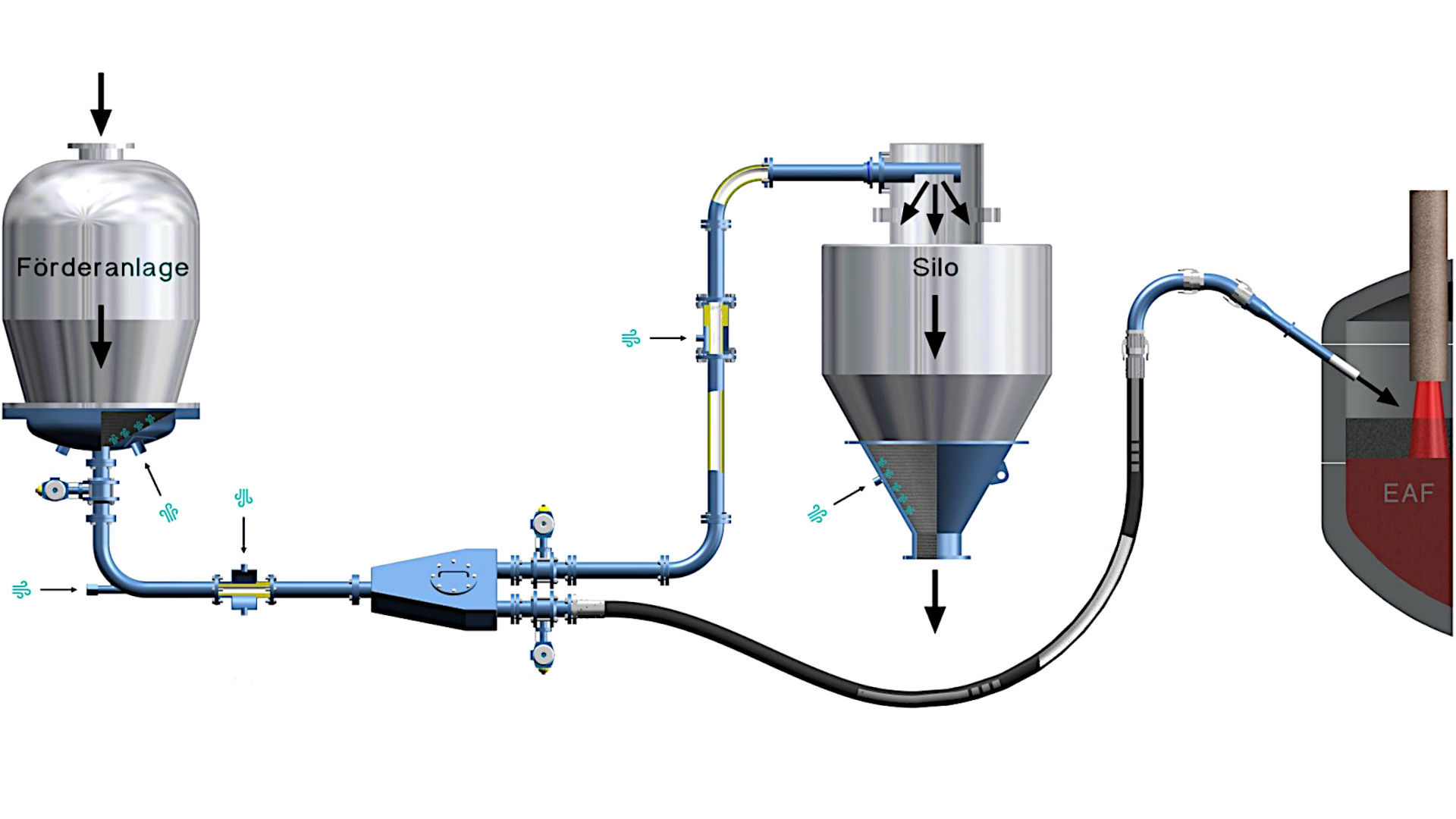

Die Firma Friedrich Gerke ist spezialisiert auf Verschleißschutz-, Förder-, Hütten- und Fluidisierungstechnik.

Wir bieten optimale maßgeschneiderte Verschleißschutzlösungen in Keramik und Stahl für alle Einsatzbereiche an.

Förderanlagen, Fördersysteme und Material-Fluidisierungen vervollständigen unsere wirtschaftlich rentable, umfangreiche Material- und Produktpalette.

Wir sind in sämtlichen Industriebereichen vertreten.

Interesse? -> Sehen Sie auf den nächsten Seiten, was wir gemeinsam verwirklichen können.